- Upgrade

- Posted

Passive Power

A passive house, by its nature, requires a much smaller amount of energy than a typical home, and when its heating demand is met by electricity, and you cover it in solar PV panels, you can start to see the potential for a whole new generation of passive homes that are semiindependent of the electricity grid. This is the case for Carrstone House in Bedfordshire, which generates so much solar energy it had to be registered as a power station.

Click here for project specs and suppliers

Building: 230 m2 detached house

Method: Timber frame

Location: Bedfordshire, England

Standard: Passive house plus

Energy bills: £46 per month for all energy including running an electric car (estimate, including April 2022 price hike.) Compared to £8 per day profit from March 2021-2022.

As energy prices soar to all-time highs, the thought of living in a house that generates much of its own power sounds appealing. This is the case for Carrstone House, in Bedfordshire, which has 91 solar PV (photovoltaic) panels providing 24 kW peak of electricity, enough to meet the equivalent of all the house’s power and heating needs, with excess to run a powerful electric Tesla Model X car and export surplus electricity back to the grid. Carrstone House has so many PV panels that it has had to be registered as a power station.

The owners, Paul and Belinda Wilson, moved into the house in 2017 after an eight month build. Their new home was constructed in the one-acre garden of their old house and achieved the passive house ‘plus’ standard, only just falling short of the passive house ‘premium’ benchmark. These additional certification categories reward passive houses that produce renewable energy. The couple decided to build their own home after their three children had grown up. They sold their old house and half the garden, and the new owners moved in just weeks after Paul and Belinda had left.

Carrstone House has so many PV panels that it had to be registered as a power station.

Paul and Belinda are very satisfied with the comfort and heat-efficiency of their passive house. “To date we have been paid more than we pay out by a few hundred pounds... in the winter it has cost us more to use electricity than we create, but in the summer we have made a significant surplus,” says Paul. “We have a 4 kW air source heat pump, which provides the heat. As part of the project, we bought a Tesla Model X including free supercharging… we’ve done 65,000 miles in five years and, with negative costs for electricity at home and free Tesla charging on the road, it hasn’t cost us a penny for fuel.”

The average annual amount of electricity generated by the panels, he says, is 19,500 kilowatts, or 1,625 kilowatts per month. But in practice it ranges widely between 200 and 3,575 kilowatts monthly. The couple’s feedin- tariff pays them about £1,500 per year. Their electricity bills were averaging about £1,320 per year, but the rate they pay for electricity is now set to increase to 29p per unit, which will push their annual bill up to over £2,000, meaning for the first time they will pay more for buying electricity than they earn for generating it. It is a sign of just how much energy prices have risen that a house with such a large solar array will now have an annual bill of about £800 (See ‘In detail’ for more on these figures).

Their new home was constructed in the one acre garden of their old house.

The surface of the roof uses an integrated PV system, with PV panels supported on an aluminium railing system. Glass was used for the perimeters to limit the amount of PV electricity provided to 24 kW peak, because the network operator said the grid could not take any more. Because the home has so many PV panels, the couple had to obtain a licence to be classified as a power station. Restricting the peak to 24 kW left the house slightly short of the passive house premium standard, but they cannot imagine living in a more comfortable home.

“The main lesson we’ve learned is we wouldn’t want to go back to living in an ordinary house. Our ambient temperature is 21 degrees and, generally, any house we visit feels cold and draughty. We’ve got used to an absolutely constant temperature,” says Paul.

“We have the heating on for about 20 per cent of the time through the winter. Heating is provided by underfloor heating installed in the slab. The foundation contractor offered it for an extra £1,200 so it was too good to miss. The other thing is we often make the mistake of going out inappropriately dressed, especially in spring. Belinda has headed off a few times in her flip-flops when it’s been cold outside.”

This article was originally published in issue 41 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €15, or click here to receive the next issue free of charge

The couple are horrified by the quality of construction of some of the new builds springing up locally. “You think it’s going to be phenomenal to heat these new homes with so little insulation and poor detailing. It’s like our home is hermetically sealed with a constant source of fresh air being pumped into us inside the pod. You have to live in it to believe it.”

Belinda and Paul bought their old house 15 years ago and in 2014 began to think about building a house in the garden, then selling the first home. An initial design was rejected by local planners based on a rule that new builds had to be either in the style of “country houses” or have something special about them. The couple immediately thought of building an environmentally efficient home. When Belinda chanced upon a YouTube video with Alan Budden of Eco Design Consultants demonstrating the care required to ensure airtightness when building a passive house, the pair were curious.

The high standards of passive house appealed to Paul, who was sceptical about what he called “cosmetic” add-ons to houses. He had worked in the construction industry as a quantity surveyor and ended up running UK operations for a major contractor. “I’d seen work on buildings with tiny windmills, wood pellet boilers and ground source pumps, but I wanted us to go much further and get the house to pay for itself,” he says. Paul was also reluctant to build a prefabricated “kit house”. The manufacturers, he said, could not confirm whether they would reach passive house standards until the design was complete, nor would they commit on price.

The couple spoke to their existing architect about designing a passive house and he advised them to find a specialist architect. They approached Alan Budden, from Eco Design Consultants, in Milton Keynes. The couple already had some clear ideas about what they wanted design-wise. The old house had far too much circulation space and they wanted to minimise it in their new home. One feature they opted to keep was a downstairs bedroom. Meanwhile, they asked for the kitchen-diner to have the best views during the day as opposed to the lounge, which was where they would put their feet up in the evening.

“When planning was [initially] refused the house design was quite tall and didn’t fit into the environment, blocking views from the old house due to the bulk and scale,” says architect Alan Budden. “We designed Carrstone House to look a little like an outbuilding down the side of the garden with a lower pitched roof, hunching down into the environment. We also dropped it into the ground to enhance the views from the former property. At the same time, Paul and Belinda liked the old house’s extension which had a vaulted ceiling. So, those two things came together to create the overall effect.”

Paul and Belinda helped to check that the new roof designs allowed good views. They conducted experiments with poles and ropes in the garden to test how obtrusive the new roof would be. They looked across from the patio and kitchen window in their old house, and were happy with the lines of sight. “We’ve enjoyed those views for years and it is no different now to what we could see before,” he says.

There was some concern when they put in for planning for the second time that the application would be refused on the grounds of “garden grabbing”, rumoured to be a significant local problem. But the council planning team said it was not yet an official policy. “They’d debated it many times, but when the planning officer checked, it turned out there was currently no rule,” says Paul.

“Alan prepared an extensive document with pictures showing the advantages of the build and the planner said they’d given permission for buildings ‘nothing like as interesting, beneficial, or sustainable’, as ours.”

The builder, Nick Hull, and sub-contractors, began on site in May 2016 and had completed the work by January 2017 when the couple moved in. In the meantime, the couple had sold their old house and the new owners arrived in February 2017. Gloucester- based MBC Timber Frame not only put up the frame, but also did all of the foundation work. “In three weeks, they had completed nearly all the work. They went away and we had the windows delivered and installed and then they came back a week later and did the air test. At that point we had a watertight, airtight building to passive house standards,” he says.

Paul’s extensive experience in construction helped to make it a smooth process. He opted to be the project manager and took on the role of principal designer, giving him responsibility for ensuring that health and safety were managed properly. He took a one-day construction, design and management course to make sure he understood the role fully. He also enforced some basic rules – every person on site had to wear a hard hat, high visibility jacket and protective boots, and everyone entering the site was inducted. Belinda also did a four-day first aid at work qualification along with the builder. There was a first aid presence on site at all times.

As the ducting was so neatly done, it was left exposed.

The finished house has large open-plan living spaces downstairs. This necessitated extra insulation in the building envelope as it made the form factor of the house worse, increasing the surface area from which heat can be lost. The single-storey living area has a sloping roof that provides one to 1.5 storey height rooms. The interior hall has views through to the living space and garden beyond. “Belinda was keen on the idea of ‘borrowed landscapes’ so the garden in the background feels part of the living space,” says Paul.

Carrstone House has Internorm triple glazed timber aluminium windows and sliding doors. The sliding doors were chosen instead of bifold ones because of their superior airtightness. “There are two large glazed units in the sliding doors, which each weigh about a quarter of a tonne. But they slide across when pushed by one finger. So, the quality is superb,” Paul says. The MVHR (mechanical ventilation with heat recovery) unit is on the ground floor in the utility room. As the ducting was so neatly done, it was left exposed to improve route efficiency and to show a key part of the passive house philosophy. Air is distributed to the bedrooms, living room and study via ducts in the first floor, and exposed ducts in the study and pantry. The air is then transferred under doors and through the hall to the kitchen and bathrooms.

When the district network operator limited the licence for electricity to 24 kW peak, other options were considered in order to reach the passive house premium standard. The couple could have bought shares in a renewable energy scheme, for example. They rejected this solution in the end, but may explore it again in the future. Direct electric heating was also assessed, but using an air source heat pump provided much greater efficiency and could also heat the domestic hot water supply. The air source heat pump and hot water cylinder supply the underfloor heating downstairs, as well as towel rails in the bathroom.

Belinda and Paul thought about using battery power, but this was difficult to do at the time as their three-phase installation would have required three different battery systems. However, Paul says the recent spike in energy price means he is now thinking again about getting a battery, and Tesla now supply a three-phase version.

The couple’s experience has been so positive that they have been happy to advise people thinking of going down the same route. “We’ve sat down with quite a few people to discuss their plans and talk about how they can achieve what they need,” says Paul. For Belinda, there is even the enticement of building another passive house. “It’s tempting to buy a plot in Norfolk, and have another go,” she says.

Selected project details

Architect & passive house design: Eco Design Consultants

Main contractor: Nick Hull Builders

Timber frame: MBC Timber Frame

Structural engineering: South Stoke Structures

Passive house certification: Etude

Building services design: Williams Energy Design

Building control: JHAI

Airtightness test: Melin Consultants

SAP assessment: Eco Energy Environmental

Power connection: UK Power Networks

Thermal breaks: Compacfoam, via Green Building Store

Windows & external doors: Internorm, via Footprint Homes

MVHR: Touchwood Building

M&E contractor: Teckos

Tesla connection: Mark Cawood

Lighting: National Lighting

EMBODIED CARBON

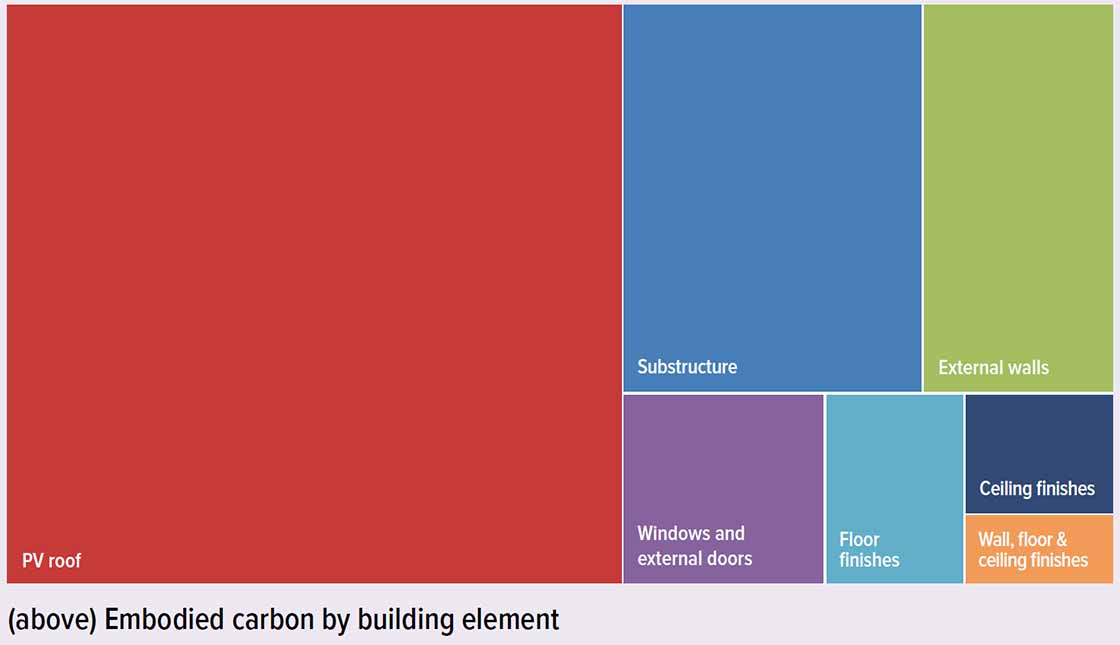

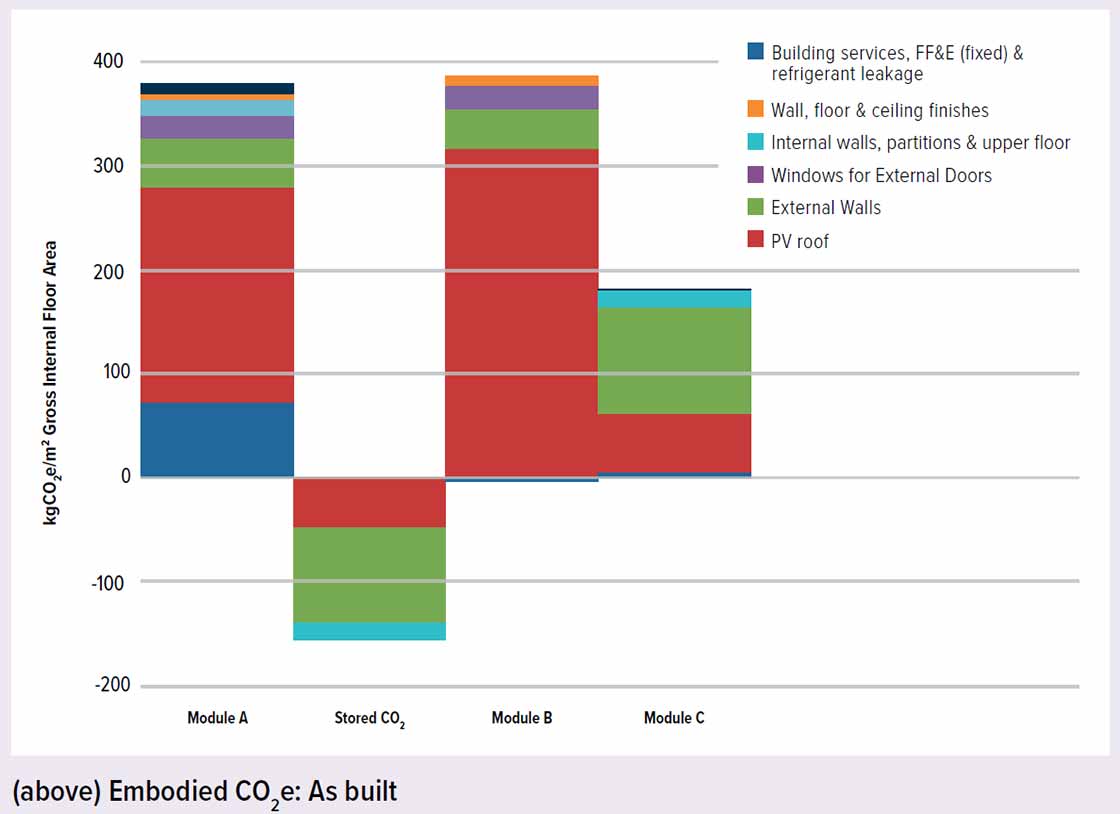

The building’s embodied carbon emissions were calculated by Tim Martel using PHribbon. The scope focuses on the house only – without the separate garage building – and included the substructure, superstructure, finishes, FF&E and building services, albeit with some items omitted. Facilitating works were not included, nor were external works. While the MVHR unit and heat pump were included – based on industry association PEPs in both cases – the associated services such as ducts, pipes and heat emitters were not, and nor were any of the electrics, with the exception of the PV array.

The EV charger, solar inverter and battery, stairs, carpets and paints weren’t included. Tiles were included, along with all bathroom fittings – but the kitchen sink was not. The biggest ticket item by far is the home’s 93-panel building integrated photovoltaic (BIPV) array, which stands at 150.3 m2 of modules, with 36 m2 of single glazed curtainwalling to the perimeters to make up the remainder of the roof. In the absence of verified embodied carbon values for the PV panels, default data for monocrystalline panels from the ICE database was used. If we stop short of the PV + perimeter glass roof, the building total stands at a cradle to grave figure of 316 kg CO2e/m2 – a highly creditable score bearing in mind the RIBA 2030 Climate Challenge target for dwellings is 625 kc CO2e/m2 GIA.

But with the PV roof included a different picture emerges. Based on a default value from the ICE Database of 242 kg CO2e per m2 of module area, the total rockets to 809 kg CO2e/m2, though the reality could in fact be worse still. Passive House Plus found a valid EPD for a different brand of monocrystalline PV module available on the UK market with independently verified embodied carbon results worse than the ICE default data, including a cradle to factory gate (A1-A3) total of 276 kg CO2e per m2. This module would bring the building’s total up to 859 kg CO2e/m2. But if PV modules like Sunpower’s Maxeon 3 was used instead, the total would drop to 490 kg CO2e/m2.

The Maxeon 3’s impressively low embodied carbon score appears to be due to a number of factors, including their use of thin wafers from Nowegian supplier NorSun, who have taken efforts to reduce their own carbon footprint. What’s more the Maxeon 3 boasts a market-leading output of 226 Wp per m2, as compared to a still respectable 205 Wp score by the brand with the higher embodied carbon EPD score.

It was assumed the array would last for 25 years, meaning the calculations allow for two full replacements of the array within the 60-year design life specified for building LCAs in the UK. But this exercise has shown that the impact of PV module choice can be stark. For an array of this size, the embodied carbon of the modules alone could vary from 35 tonnes for an array with higher output, to over 125 tonnes for an array with a lower output, which would be over 61 per cent of the whole building total. A health warning must be applied here: as no EPD or PEP was available for the modules used in Carrstone House, it’s not possible to determine whether the default values used reflect the actual system installed.

One factor which helped reduce the building’s embodied carbon score was the decision to opt for a heat pump which uses CO2 as its refrigerant, a Mitsubishi Ecodan QUHZ. The global warming of R410A – a refrigerant which dominated the market when Carrstone House was under construction – is 2088, meaning each kilo in the machine represents 2.088 tonnes of CO2e. According to CIBSE TM65, a document which defines how to calculate the embodied carbon of building services, a leakage rate of 2 per cent is assumed per annum, and a further 1 per cent leakage at the building’s end of life. While Mitsubishi has completed TM65 calculations of its outdoor units, the absence of calculations for the indoor unit led to data for air source heat pumps from French industry association Uniclima being used, albeit with the refrigerant substituted out for CO2 – meaning a kilo of refrigerant only contains a kilo of CO2e.

The total is also reduced by the build system – Larsen Truss timber frame filled with cellulose insulation, and with an Aquapanel render board externally. In spite of the use of 28/35 reinforced concrete made with CEM I, the insulated foundation system likely helped reduce the embodied carbon too, by reducing concrete use compared to conventional foundations.

Construction in progress

-

The insulated foundation system features 300 mm of Kore EPS

The insulated foundation system features 300 mm of Kore EPS

The insulated foundation system features 300 mm of Kore EPS

The insulated foundation system features 300 mm of Kore EPS

-

Airtightness taping to ProPassiv panels and ductwork for MVHR system

Airtightness taping to ProPassiv panels and ductwork for MVHR system

Airtightness taping to ProPassiv panels and ductwork for MVHR system

Airtightness taping to ProPassiv panels and ductwork for MVHR system

-

The roof light seen here was formed on site with a triple-glazed panel in the PV curtain-walling system, while exposed MVHR ducting is also visible here

The roof light seen here was formed on site with a triple-glazed panel in the PV curtain-walling system, while exposed MVHR ducting is also visible here

The roof light seen here was formed on site with a triple-glazed panel in the PV curtain-walling system, while exposed MVHR ducting is also visible here

The roof light seen here was formed on site with a triple-glazed panel in the PV curtain-walling system, while exposed MVHR ducting is also visible here

-

The roof light seen here was formed on site with a triple-glazed panel in the PV curtain-walling system, while exposed MVHR ducting is also visible here

The roof light seen here was formed on site with a triple-glazed panel in the PV curtain-walling system, while exposed MVHR ducting is also visible here

The roof light seen here was formed on site with a triple-glazed panel in the PV curtain-walling system, while exposed MVHR ducting is also visible here

The roof light seen here was formed on site with a triple-glazed panel in the PV curtain-walling system, while exposed MVHR ducting is also visible here

-

Installation of underfloor heating pipework, DPM and reinforced steel mesh, to be followed by concrete slab

Installation of underfloor heating pipework, DPM and reinforced steel mesh, to be followed by concrete slab

Installation of underfloor heating pipework, DPM and reinforced steel mesh, to be followed by concrete slab

Installation of underfloor heating pipework, DPM and reinforced steel mesh, to be followed by concrete slab

-

Erection of the MBC timber frame system underway, which is insulated with Warmcel, and the SmartPly ProPassiv panels fitted to the inside delivering outstanding levels of airtightness

Erection of the MBC timber frame system underway, which is insulated with Warmcel, and the SmartPly ProPassiv panels fitted to the inside delivering outstanding levels of airtightness

Erection of the MBC timber frame system underway, which is insulated with Warmcel, and the SmartPly ProPassiv panels fitted to the inside delivering outstanding levels of airtightness

Erection of the MBC timber frame system underway, which is insulated with Warmcel, and the SmartPly ProPassiv panels fitted to the inside delivering outstanding levels of airtightness

-

Erection of the MBC timber frame system underway, which is insulated with Warmcel, and the SmartPly ProPassiv panels fitted to the inside delivering outstanding levels of airtightness

Erection of the MBC timber frame system underway, which is insulated with Warmcel, and the SmartPly ProPassiv panels fitted to the inside delivering outstanding levels of airtightness

Erection of the MBC timber frame system underway, which is insulated with Warmcel, and the SmartPly ProPassiv panels fitted to the inside delivering outstanding levels of airtightness

Erection of the MBC timber frame system underway, which is insulated with Warmcel, and the SmartPly ProPassiv panels fitted to the inside delivering outstanding levels of airtightness

-

Erection of the MBC timber frame system underway, which is insulated with Warmcel, and the SmartPly ProPassiv panels fitted to the inside delivering outstanding levels of airtightness

Erection of the MBC timber frame system underway, which is insulated with Warmcel, and the SmartPly ProPassiv panels fitted to the inside delivering outstanding levels of airtightness

Erection of the MBC timber frame system underway, which is insulated with Warmcel, and the SmartPly ProPassiv panels fitted to the inside delivering outstanding levels of airtightness

Erection of the MBC timber frame system underway, which is insulated with Warmcel, and the SmartPly ProPassiv panels fitted to the inside delivering outstanding levels of airtightness

-

Breather membrane and Aquapanel render board fitted to the external side

Breather membrane and Aquapanel render board fitted to the external side

Breather membrane and Aquapanel render board fitted to the external side

Breather membrane and Aquapanel render board fitted to the external side

-

Breather membrane and Aquapanel render board fitted to the external side

Breather membrane and Aquapanel render board fitted to the external side

Breather membrane and Aquapanel render board fitted to the external side

Breather membrane and Aquapanel render board fitted to the external side

-

A section of the 91 panel roof-integrated PV system, with PV panels supported on an aluminium railing system, and glass to perimeter

A section of the 91 panel roof-integrated PV system, with PV panels supported on an aluminium railing system, and glass to perimeter

A section of the 91 panel roof-integrated PV system, with PV panels supported on an aluminium railing system, and glass to perimeter

A section of the 91 panel roof-integrated PV system, with PV panels supported on an aluminium railing system, and glass to perimeter

-

Airtightness taping to ProPassiv panels and ductwork for MVHR system

Airtightness taping to ProPassiv panels and ductwork for MVHR system

Airtightness taping to ProPassiv panels and ductwork for MVHR system

Airtightness taping to ProPassiv panels and ductwork for MVHR system

https://mail.passive.ie/magazine/upgrade/passive-power#sigProId5099ba7068

In detail

Building type: 230 m2 detached two-storey timber frame house.

Location: Bedfordshire

Completion date: July 2017

Budget: £528,000 including fees.

Passive house certification: Passive house plus certified

Space heating demand (PHPP): 16 kWh/m2/yr

Heat load (PHPP): 10 W/m²

Primary energy demand (PHPP): 83 kWh/m²/yr

Heat loss form factor (PHPP): 3.09

Overheating (PHPP): 4 per cent

Airtightness (at 50 Pascals): 0.27 ACH

Energy performance certificate (EPC): A 136

Energy use & generation: Paul and Belinda’s energy consumption of grid electricity has averaged approximately 7,500 kWh per year. However, their 24 kW peak solar PV array has generated, on average, 19,500 kWh per year, about 2.5 times what they import.

Energy bills: Paul and Belinda's average annual energy bill has increased from approximately £1,125 in 2017 to an anticipated £2,156 for the next calendar year (inc VAT and standing charges), as their electricity rate has increased from 15p per kWh in 2017 to 27p in 2022. Their standing charge has also increased from 19p per day to 36p per day (or from £69 to £131 per year).

The couple recieves an annual fee for generating electricity of approximately £1,600 per year, comprised of both a feed-in-tariff and an export allowance. This means that, with the recent hike in energy prices, the couple will soon make a net loss on their annual energy bills of approximately £556 per year, or £46 per month, after five years of making a net positive on their bills. They will continue to make a significant surplus in summer due to high power generation, but will incur the total cost of their power during winter months.

Thermal bridging: Use of the MBC timber frame with Larson truss to reduce thermal bridging in wall and at foundation, additional Compacfoam used at door thresholds. Additional insulation around window frames to reduce thermal bridging. SVP vent pipes eliminated by venting manhole.

Ground floor: Hardcore and sand blinding, followed above by DPM, 300 mm EPS100 (λ=0.036), separating layer, 100 mm reinforced concrete slab with underfloor heating pipes (thicken to 200 mm x 600 mm wide at perimeter, and load bearing walls). Power-floated finish. U-value: 0.117 W/m2K

Walls: K-Rend external render on Aquapanel render board, followed inside by 50 mm ventilated void with battens, 12.5 mm Medite Vent panel board, 300 mm Larsen Truss timber frame by MBC with plywood gussets and Warmcel insulation between, 12.5 mm SmartPly Propassiv board internally taped with Siga tapes to form airtightness layer, 38 mm service void formed with battens, 12.5 mm plasterboard plus skim. (One external elevation render board replaced with 150 mm stone blocks). U-value: 0.12 W/m2K

Roof: 80 mm PV curtain walling system externally, with aluminium rails supporting PV panels, and glass to perimeter, followed underneath by 35 x 50 battens and counter battens, Amacol Areo Plus breather membrane, 400 mm MBC Larsen Truss roof panel, with plywood gussets and filled with Warmcel insulation, Siga airtightness membrane, 38 mm service void formed with battens, 12.5 mm plasterboard plus skim. U-value: 0.11 W/m2K

Windows & external doors: Internorm HF 310 from Footprint Homes. Sealed with Siga tapes. Roof windows: Formed on site with triple glazed panel in PV curtain walling system and insulated kerb.

Heating system: Mitsubishi Ecodan PUHZ-W50VHA-5KW, with integral hot water tank – 170 litres ErP class C. Feeding underfloor heating on ground floor, and heated towel rails in bathrooms on first and ground floors.

Ventilation: Paul Novus 300 with summer bypass.

Water: Restricted waterflow showerheads. Water from roof to water butts, then overflow into pond and then second soakaway pond in garden.