- New build

- Posted

Pitch perfect - Beguiling Dundee passive house puts wood into woodland

An intriguing new passive house in Dundee takes the traditional ‘box’ form associated with the standard and turns it on its head, using a series of pitched roofs and different claddings to make it feel more like a traditional city terrace than a single dwelling – built with a heavy emphasis on carbon sequestering materials.

Click here for project specs and suppliers

ENERGY BILLS £106 PER MONTH FOR ALL HEATING, HOT WATER AND ELECTRICITY

Building: 181 m2 detached dwelling

Build method: Timber frame

Location: Dundee, Scotland

Standard: Uncertified passive house

Fenton House lies in a little oasis of beautiful old woodland in suburban Dundee. It is around 10 minutes by bike from the city centre, in the former grounds of Invergowrie House, a turreted fort built between the fourteenth and sixteenth centuries. From the second storey of this upside-down passive house there are wonderful views over the top of the wood and the surrounding cityscape, to the ever-changing light of the Tay Estuary.

For owners David and Jenny Arrenberg, the warmth and comfort of Fenton House makes a welcome contrast with the freezing cold flat they previously occupied in Invergowrie House.

“Living in Fenton House is ‘pinch yourself’ time,” says David, who works as an engineer for Scottish Water. “Before we started to build, I used to climb the trees to make sure we’d be able to see into the distance from the top floor. We can! The views of the river are gorgeous. There are lots of tidal changes and you get sand banks one minute and it’s choppy the next. We can see as far as Kinnoull Hill in Perth.”

As for the warmth, David spent a lot of the winter Covid-19 lockdown working from home in shorts and a T-shirt. “Our north-facing flat in Invergowrie House was the exact opposite. It was a converted storage room on the ground floor and slightly underground. There were zero passive house principles involved and it was freezing in winter. The difference with Fenton House is about 20 degrees!”

The joy, however, is tinged with sadness. David’s father was a major inspiration for the project, but he passed away before it broke ground. “Dad was a man of many trades, an officer in the navy, a tree surgeon, and a picture framer, but he went on to become a plumber and builder. His talent as a tradesman was painting and stenciling — he was a very creative chap,” David says.

His father had always encouraged David to convert the plot of land — gifted by his aunt — into a permanent home. “To say I am disappointed he didn’t get to see the house is an understatement. I think about it daily. My dad always wanted to build his own house, but never had the money. He used to go on at me about building on the plot. And we worked on the woodland together with my brother from when I was nine years old. I kept finding reminders of him around the land, old bottles, tools and materials. His memory drove me on to do a good job when the work was hard,” he said.

Living in Fenton House is ‘pinch yourself’ time.

David is not native to Dundee, or Scotland. He was born in Bromley North, in London, and moved up with his English parents in 1987 when he was three and his brother was eight. He soon adopted the local accent, whereas his older brother has retained a London twang.

The family lived in Invergowrie House, which was split into four flats with the attached land divided between the owners. His aunt and uncle occupied the most spacious flat and had the largest, seven-acre plot.

In 2003, after the death of her husband, his aunt went to live in Herefordshire. But she kept hold of about three acres of the land, with its magnificent 250-year-old cedars and oaks. Given David wanted to live in Dundee, and his keen interest in building a home, his aunt decided to offer him the land and the opportunity to build here.

In 2015, David and his wife Jenny moved into the ground-floor flat at Invergowrie House. In the same year, they hired Kirsty Maguire, a Dundee architect specialising in the passive house standard, to design their home. They already had some clear ideas. They wanted an open-plan living space upstairs to take advantage of the views. The couple also wanted a low energy house. David’s civil engineering background meant he was knowledgeable about sustainable design.

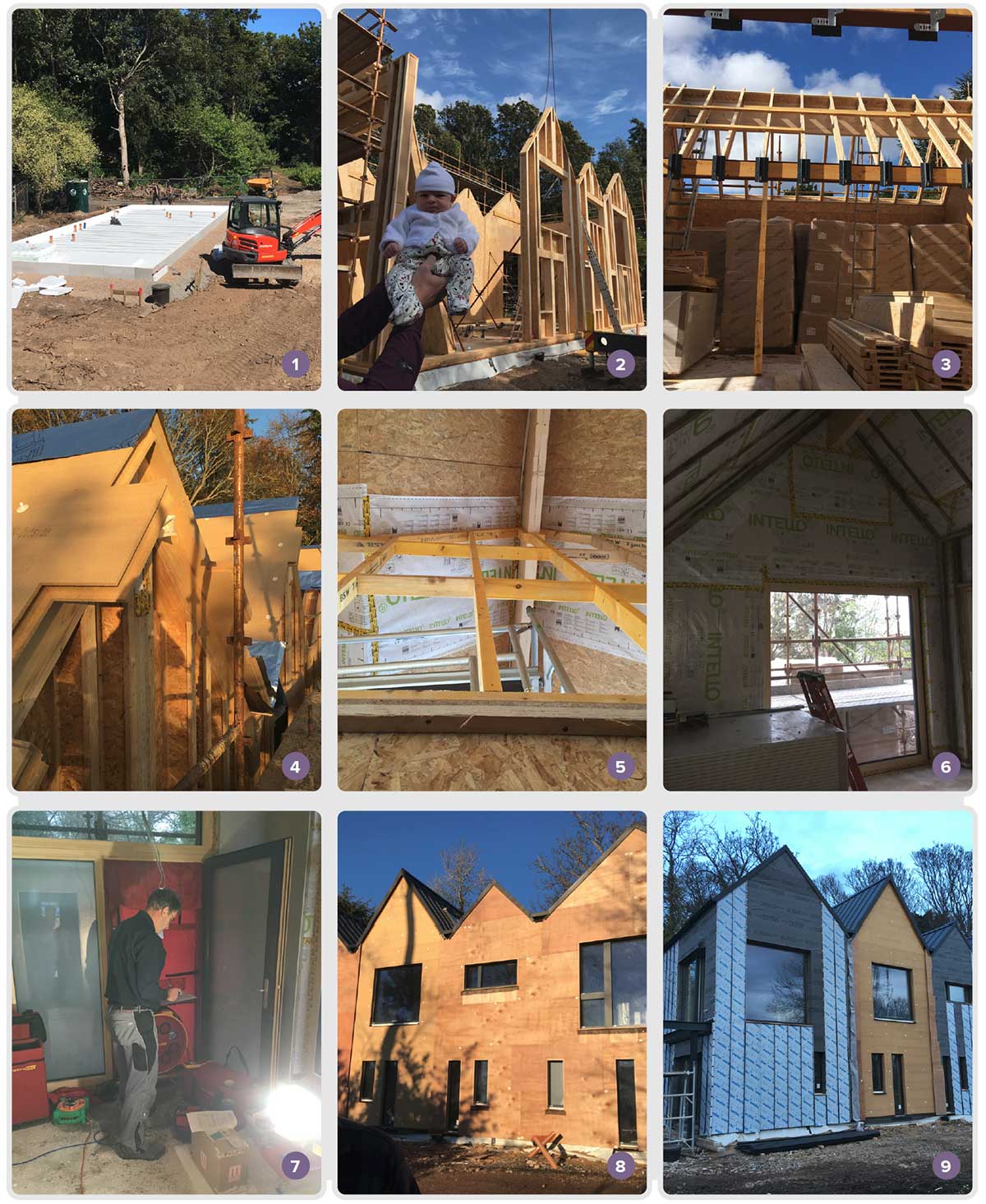

1 Insulated raft foundation to minimise thermal bridging; 2 the timber frame sections being craned into place, with baby for scale; 3 Steico wood fibre batts, seen here waiting to be installed, were used throughout the walls and roof to insulate the I-joists; 4 while Steico wood fibre boards were used externally on the roof and walls; 5 each of the roof apexes has a glulam beam and an airtight layer above it; 6 airtightness membrane to walls and roof, and taping around thermally broken windows; 7 a blower door airtightness test being carried out; 8 & 9 plywood was installed over the Steico wood fibre board on three of the four sections, with zinc cladding then attached to the plywood, while the fourth section was clad with larch.

“The open plan could have made it feel a bit cavernous, lacking in character and over-reliant on the great views. But I designed a series of four pitched roofs,” said Kirsty. “The dining space, living room and kitchen are each defined volumetrically by the vaulting of the roofs. It gives them the feel of semi-separate rooms. Basically, we kept to a simple rectangular box — which was great for achieving passive house and cost management — but invested in a more complicated roof.”

Each of the apexes has a glulam beam and an airtight layer that goes over the top of it. “You have to make sure the airtightness membrane is in place as you build, as it exposes the glulam beams. They are very beautiful and part of the expression of the space. But it needs to be carefully thought out and installed,” said Kirsty.

This article was originally published in issue 38 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €10, or click here to receive the next issue free of charge

She specified low carbon materials, including wood-fibre insulation and a timber structure. The insulation came from Steico, and Kirsty said that she specifically chose wood-fibre due to its decrement factor — the time it takes for a peak daily temperature outside to become a peak daily temperature inside.

Wood-fibre is better at controlling this decrement factor than lighter synthetic insulations, thus helping to prevent overheating. For the cladding, Kirsty chose Scottish larch and recyclable long-lasting zinc. Meanwhile, an air source heat pump was installed to provide constant hot water. The house was also equipped with an MVHR system, photovoltaic panels, and electric infra-red panels for space heating.

I designed a series of four pitched roofs.

Although the plans were submitted in 2015, getting approval was a slow process. The exact location of the house had to be moved a little after neighbours on the adjacent housing estates expressed concern that it would overlook their properties. David also had to put in place a woodland maintenance plan to ensure the protection of the mature trees. Another issue was fire engine access, which the council deemed essential. Meanwhile, David and Jenny were not even ready to begin immediately. They were busy scraping together all the money they needed to pay for the project. The total cost ended up at around £330,000, including Kirsty’s fee.

Work eventually began in May 2018 and took a year to complete. The contractor, Craigs Eco Construction from Linlithgow, had experience building passive houses and offered a flexible way of working that left David free to find cheaper prices for much of the work. “I hired plasterers, electricians and plumbers directly and Craigs Eco were happy to work with them. It saved quite a lot of money,” he said.

Even greater sums were saved by David’s relentless bargaining over materials. “I was pretty ruthless when it came to bartering down prices. The zinc looks tremendous, but the original quote was for £95,000. I ended up getting it down to £54,000. My Excel spreadsheet never left my side and I reckon I saved over £60,000 arguing over quotes and going round and round in search of cheaper suppliers,” he said.

With his flexible working hours, and home base at Invergowrie House, David was able to act as a second project manager. He carried out his own quality checks and was available if Craigs Eco could not be on site first thing in the morning. Working for Scottish Water proved useful as he personally knew the water and sewage engineers that worked on the house.

One of the most joyful moments came when the Polish joiners put together the wooden frame on site. “It would have been tricky to build it off site and then crane it in as there wasn’t a lot of space. They constructed the ten massive panels on the foundation slab, then we pulled them into place with a crane. They all slotted together like Lego, and it was one of the most fun things I’ve ever seen. The joiners only spoke broken English, but they worked overtime and I was so impressed I gave them a bonus of a bottle of whisky and a wood-turning machine,” David said.

The construction process went smoothly, and the couple moved into the house in June 2019, with baby Ruby who was born at the start of the construction process. There was still work to do furbishing the house with contemporary designs, which Jenny had lots of ideas about. But right from the start, living in Fenton House was an almost surreal experience of comfort and spaciousness after four years in a cold basement flat.

Even during lockdown, with the entire family at home, bills have been low. “Our electric bills were about £1,200 for the year and we are running an electric car, an electric mower to cope with gardening on an industrial scale. And Jenny, who is a partner in a dental practice, has been running three loads of the washing machine every day of the week because of all the PPE gear. Heating has cost virtually nothing,” said David.

Having the bedrooms on the ground floor makes them slightly cooler, but David and Jenny like it that way. On the rare hot Dundee days, the building’s natural ventilation is able to cool the house. Opening the roof lights can draw air through the whole building. The sliding patio doors are another option. The house is also set up to meet accessibility requirements.

It could be retrofitted with a stairlift and there is space for wheelchair storage. Kirsty says it would even be possible to set it up as a ground-floor flat only. The couple have no plans to move anywhere else. “David is planning to be carried out in a box,” she said.

David believes Fenton House will be a magical place for his children (the couple had another baby just as Passive House Plus went to print, after we interviewed David for this article).

He has built a large climbing frame, but when they tire of that, there are all the mature trees to climb. Deer and foxes are seen daily. “I couldn’t imagine a better house for a family. Ruby is the jammiest kid in Dundee and the next child will be even luckier. We get loads of people coming to visit, and it inspires them to think about building their own passive houses.”

Selected project details

Client: David & Jenny Arrenberg

Architect: Kirsty Maguire

Structural design: Burnett Consulting Engineers

Passive house designer: Kirsty Maguire

Main contractor: Craigs Eco Construction

Ventilation: Paul Heat Recovery Scotland

Air source heat pump: Luths Services

Windows & doors: Green Building Store

Wood fibre insulation: Steico

Airtightness testing: Thermal Image Scotland

Insulated foundation: Advanced Foundation Technology

Roof windows: Fakro

Zinc cladding: HL Metals

Flooring: West End Flooring

Lighting: Terkan

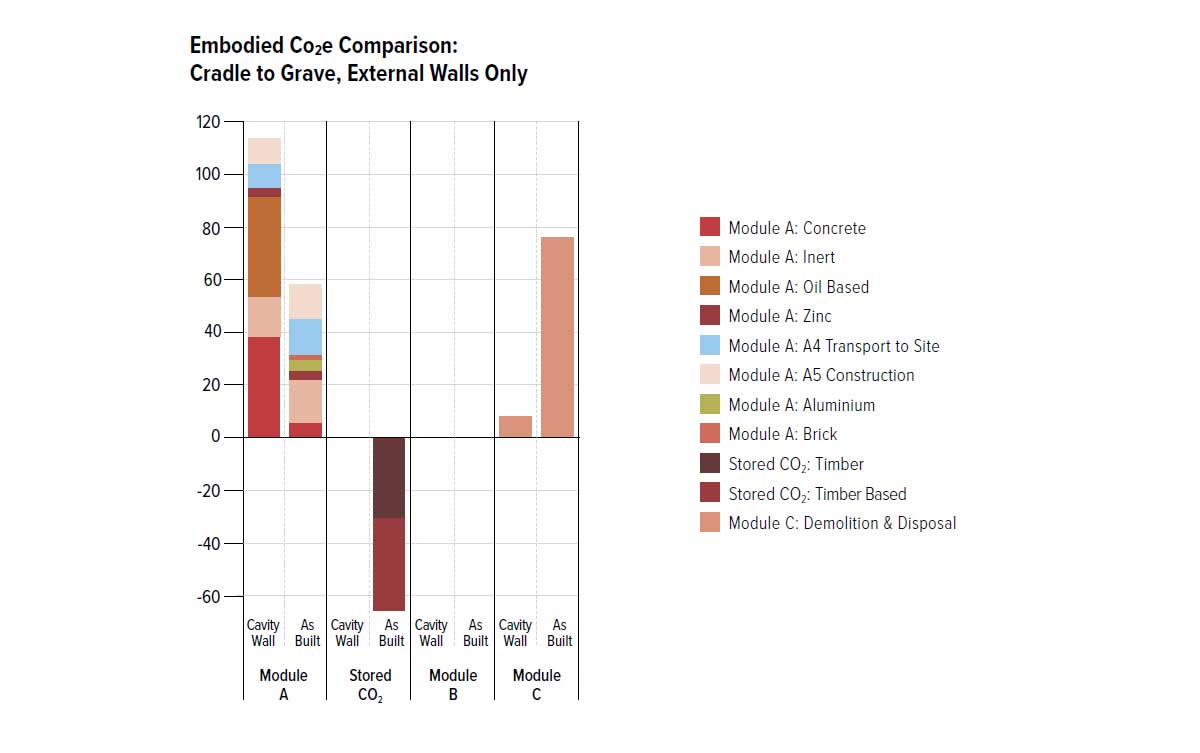

Embodied carbon

An analysis of the building’s whole life carbon score was conducted by John Butler Sustainable Building Consultancy, using PHribbon.

Based on a cradle-to-grave analysis, the building totalled 496.8 kg CO2e/m2 GIA – a total which in large part reflects the fact that the analysis assumes the stored CO2e from the timber and timber-based products is released after sixty years (the standard lifespan for the assessment, in line with the RICS whole life carbon methodology.)

From cradle to practical completion, however, the building has a total of 353 kg CO2e/ m2 GIA, with a further 216 kg CO2e/m2 stored in the timber and timber-based products at that point.

The analysis also compared the as-built external walls against a cavity wall version to the same spec. The as built walls showed a small reduction compared to the cavity wall when considered on a cradle to grave basis, from 221 kg CO2e down to 194 kg CO2e/m2.

But at practical completion, the difference is far more marked: 224 KG CO2e down to 154 kg CO2e – and with 131 kg of stored CO2e in the as-built walls, versus just 15 kg in the cavity walls.

The analysis included the external envelope, internal walls, floors, and finishes. The stairs were excluded, as was the balcony, and the only internal fixtures included are the sinks/basins/WCs. Due to the absence of environmental product declarations for the heat pump, MVHR system and ductwork, data from the closest comparable certificates was used, drawing from the Product Environmental Passport database – albeit with data for stainless steel ductwork instead of the polypropylene ductwork that was used. The analysis assumed no replacements of building fabric during the projected sixty-year life but assumed three replacements of the hot water heat pump, two replacements of the hot water pipes, sanitary ware and sinks, and one replacement of the PV array and MVHR system. The radiant panels and electric towel rails weren’t included, due to lack of data.

The entire superstructure of internal and external walls and roof (and window frames, excluding any aluminium cladding) is made from timber and timber-based products, so it’s perhaps unsurprising that they represent the largest chunk of embodied carbon in the building, at a combined total of almost 84 kg CO2e/m2 – though they also provide over 216 kg of sequestered CO2e, meaning these materials store more than 2.5 times as much CO2 as their manufacturing process emitted – at least for as long as they remain in the building. The next largest chunk of emissions is the zinc cladding and roofing at almost 57 kg CO2e/m2, followed by the PV at 50 kg CO2e/m2, and the concrete from the foundations at 38 kg CO2e/m2, with inert products – including glazing, plasterboard, plaster and ceramics – at 34 kg CO2e/m2, with over 39 kg CO2e/m2 relating to bringing materials from the factory gate to the site. Much of this is specific to the concrete – over 42 per cent of that figure is associated with the concrete supply.

A treemap lays the cradle to grave figures bare: building-related services, including the PV array, the hot water heat pump and MVHR system, represent 27 per cent of the total, with the roof, external walls and substructure at 20, 18 and 16 per cent respectively.

Although triple glazed windows have been criticised as being too high an embodied carbon cost by some high-profile life cycle assessment experts, in this case the total for windows, doors and rooflights only reaches 5 per cent of the total.

In detail

Building type: 181 m2 detached two-storey timber framed house.

Location: Dundee, Scotland

Completion date: May 2019

Budget: £330,000 approx, including all fees Passive house certification: Not certified Space heating demand (PHPP): 15.5 kWh/ m2/yr (PHPP carried out at design stage) Heat load (PHPP): 11.2 W/m2

Primary energy renewable (PHPP): 55 kWh/m2/yr

Primary energy non-renewable (PHPP): 110 kWh/m2/yr

Heat loss form factor (PHPP): 3.27

Overheating (PHPP): 0 per cent of the year above 25C

Number of occupants: 4

Environmental assessment method: N/A

Airtightness (at 50 Pascals): 0.66 m3/hr/m2

Energy performance certificate (EPC): A 93

Measured energy consumption: 6,697 kWh or 37 kWh/m2 (August 2019 to August 2020, measured electricity consumption).

Thermal bridging: Insulated raft foundation to minimise slab edge thermal bridge; I-joist construction with continuous wood fibre external insulation around all walls and roof to minimise thermal bridges; acrylic fixings for external wood fibre insulation; over-insulated window frames; thermally broken windows; thermal bridges designed out as far as possible through overall design. Valley gutters over-insulated to minimise thermal bridges.

Energy bills (measured): £1,425 per year, for all electricity (includes space heating and hot water). This includes charging an electric car and electric mower for the grounds. Minus an average annual feed in tariff of £150 gives a net energy bill of £1,275 per or £106 per month.

Ground floor: 150 mm compacted base, followed above by 25 mm sand blinding, 1 mm damp proof membrane, 250 mm EPS insulation, 200 mm reinforced concrete slab, floor finish. U-value 0.124W/m2K

Walls: Zinc or timber rainscreen cladding, followed inside by 50 mm ventilated cavity, 100 mm Steico wood-fibre board, 240 mm I joists stuffed with Steico wood-fibre batts, 12 mm OSB, Intello Plus airtightness membrane, 50 mm services cavity with softwood battens, plasterboard. U-value 0.115 W/m2K

Roof: Zinc roofing, on 22 mm softwood sarking boards, on 50 mm ventilated cavity with 50x50 mm softwood boards, on 100 mm Steico wood-fibre board externally, followed beneath by 240 mm I joists stuffed with Steico wood-fibre batts, 12 mm OSB, Intello Plus airtightness membrane, 50 mm services cavity with softwood battens, plasterboard. U-value 0.116 W/m2K

Windows & external doors: Green Building Store Progression triple glazed windows. Passive House Institute ‘A’ certified component. Standard whole window U-value: 0.68 W/m2K. Green Building Store Ultra doors.

Roof windows: 3 x Fakro U8 triple glazed roof windows. U-value: 0.8 W/m2K

Heating system: Ecocent Ambient air source heat pump for water heating only with 300 litre integrated cylinder. Space heating provided by Trotec infrared panel heaters and low wattage towel rails.

Ventilation: Zehnder ComfoAir Q350 heat recovery ventilation system. Passive House Institute certified to have heat recovery rate of 90 per cent. EN 308 certified efficiency of 93-96 per cent.

Water: Rainwater soakaway as opposed to connection to sewer.

Electricity: 3.99 kWp solar photovoltaic array, ground mounted. Provides electricity to general household supply with any excess exported to the grid.

Green materials: Wood fibre insulation for all floors and walls, timber cladding (heat treated larch), fully recyclable zinc cladding, insulated foundations, glulam beams, locally sourced timber frame.

Image gallery

-

Pr sections 1

Pr sections 1

Pr sections 1

Pr sections 1

-

Airtightness

Airtightness

Airtightness

Airtightness

-

Midfloor detail

Midfloor detail

Midfloor detail

Midfloor detail

-

Ridge detail

Ridge detail

Ridge detail

Ridge detail

-

Verge detail

Verge detail

Verge detail

Verge detail

-

Valley detail

Valley detail

Valley detail

Valley detail

-

Valley gutter section detail

Valley gutter section detail

Valley gutter section detail

Valley gutter section detail

-

Typical window detail plan - zinc

Typical window detail plan - zinc

Typical window detail plan - zinc

Typical window detail plan - zinc

-

Typical Window Detail Section with blind recess - Zinc

Typical Window Detail Section with blind recess - Zinc

Typical Window Detail Section with blind recess - Zinc

Typical Window Detail Section with blind recess - Zinc

-

Full Height Window Section - Zinc

Full Height Window Section - Zinc

Full Height Window Section - Zinc

Full Height Window Section - Zinc

-

Typical Window Plan and cladding setting out - Timber

Typical Window Plan and cladding setting out - Timber

Typical Window Plan and cladding setting out - Timber

Typical Window Plan and cladding setting out - Timber

https://mail.passive.ie/magazine/new-build/pitch-perfect-beguiling-dundee-passive-house-puts-wood-into-woodland#sigProId3ce7c653ee